ABVC BioPharma announces approved plan for pilot Good Manufacturing Practice (GMP) facility to produce Vitargus

The plan is intended to upgrade Vitagrus’ manufacturing process so that it can ultimately handle the global market supply.

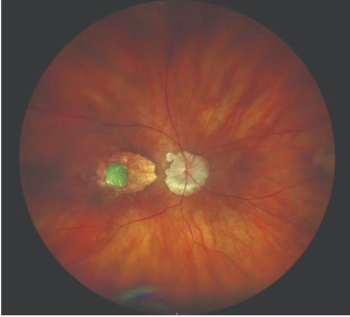

ABVC BioPharma has announced the approval of the plan by the Science Park Administration in Taiwan for setting up a pilot Good Manufacturing Practice (GMP) facility to produce Vitargus, a product for retinal detachment surgery, and to pursue the process development work for manufacturing optimization. The plan, presented by BioFirst, ABVC’S Taiwan co-development partner and affiliate, is intended to upgrade Vitagrus’ manufacturing process so that it can ultimately handle the global market supply.

BioFirst has a mission of developing, manufacturing, reaching and securing exclusive global rights to innovative patented medical products. BioFirst has secured Vitargus, the first biodegradable hydrogel product used in retinal detachment surgery from the National Health Research Institutes (NHRI).

"Vitargus® has successfully completed the feasibility study in Australia and was approved by the Australian Therapeutic Goods Administration (TGA) to initiate the next phase of trials, which is vital to obtaining approval of Vitargus® in Australia," said the CEO of ABVC, Dr Uttam Patil. "By developing our facility’s infrastructure, we expect to significantly reduce expenses associated with the ongoing trial and ensure streamlined production processes, minimize costs associated with contracting external CROs, ensure enhanced efficiency, all of which we believe will increase profitability for ABVC BioPharma and its investors. Obtaining necessary Medical Devices GMP and International Organization for Standardization (ISO) certifications is ABVC’s priority, reinforcing our commitment to quality and compliance."

According to iHealthcare Analyst, Inc, the global market for retinal surgery devices is expected to reach $4.3 billion by 2029, at a CAGR of 7.7%, driven, in part, by the rising geriatric population worldwide.²

References

1. ABVC BioPharma, Inc. ABVC announces the approval of the plan for GMP production facilities of Vitargus by Taiwan Science Park Administration. GlobeNewswire News Room. August 3, 2023. Accessed August 8, 2023. https://www.globenewswire.com/news-release/2023/08/03/2718167/0/en/ABVC-Announces-the-Approval-of-the-Plan-for-GMP-Production-Facilities-of-Vitargus-by-Taiwan-Science-Park-Administration.html

2. iHealthcareAnalyst Inc. Global retinal surgery devices market $4.3 billion by 2029. iHealthcareAnalyst, Inc. - Healthcare Market Research. May 3, 2023. Accessed August 8, 2023. https://www.ihealthcareanalyst.com/technological-advancement-ophthalmic-surgery-retinal-surgery-devices-market/

Newsletter

Keep your retina practice on the forefront—subscribe for expert analysis and emerging trends in retinal disease management.